Brake Caliper Overhaul

The following article was prepared and written by Warchild ( Dale )..

He has done all the manual work, the photography and the write up which has made the job easy to understand and to follow.

Whilst preparing to install some new

brake pads and Spiegler lines, I thought I'd get off my lazy arse

and actually disassemble my woefully neglected callipers to

thoroughly clean and inspect. I probably should have gone ahead and

replaced seals and all, but just forcing myself to clean/inspect was

a feat by itself!

Right, off we go, then.....

First, you take your MityVac and suck out every trace of old, nasty

brake fluid from the brake system as clearly outlined in Chap 15 of

your Honda Blackbird Service Manual. Before you crack open your

first bleed nipple, suck out the master cylinder until it's

bone-dry:

Here is my neglected, nasty-ass crusty left front caliper:

Close-up of the pistons all caked

with road splooge from 60,000+ miles of use. Bad Warchild.... dirty

callipers, Bad, BAD!!

![]()

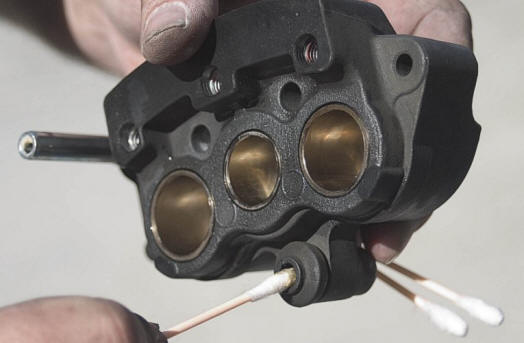

Break the callipers halves apart by removing the three callipers body bolts (12mm socket) on the non-piston side of the assembly. Note Honda's use of red loctite on the trailing threads of the bolts. You'll be working the ratchet handle to the bitter end:

Pull the pistons out far enough to expose all the crusty brake spooge (yellow arrow) so you can thoroughly clean them. You could go whole hog and replace all seals at this point if you felt so inclined. Me, I elected just to clean the dog-fuck out of the assembly, and keep going.

Using a non-petroleum based cleaner, scrub all the crusty road spooge off the pistons and calliper body:

Now flush your shiny-clean piston with clean hydraulic fluid and re-insert it into its respective cylinder:

Now clean out all the old dried, caked-up lube remaining inside the slider pin boots (obviously, replace these boots if they are damaged/torn):

And thoroughly lube up the interior of the slider boots with an appropriate grease of your choice:

( Ed note: only use proper rubber grease meant for this job. Other types of grease may cause the rubber to bind on the slider pins causing binding and rapid wear of pads )

Apply a thin layer of this same lube on your slider pins....

And finally, reassemble these bad boyz:

Although the Service Manual calls for new calliper assembly bolts, frankly, you're safe to use the old ones if they are in good shape, cleaned of old thread-locker, etc. Here I'm applying Loctite Blue to the trailing threads of the calliper assembly bolts prior to reassembly:

Torque these bolts down to 24ft-lbs

(32N-m).... now, don't be messing this one away!!!

![]()

DONE! All cleaned, lube'd, reassembled and ready for some brake pads and Spiegler lines!